Jtech 44w Laser Mm/min Material Test Plywood, Features & More

Introduction

The JTech 44W laser is a versatile and powerful tool, designed to meet the needs of makers and creators across a wide range of projects. Its precision and adaptability make it an invaluable asset for working with various materials, including wood, metal, acrylic, and more. Among these, plywood stands out as a popular choice due to its availability, affordability, and suitability for both cutting and engraving applications. However, to maximize the laser’s potential and achieve consistently high-quality results, it’s essential to understand and optimize its settings specifically for plywood.

Plywood, as a material, presents unique challenges when it comes to laser cutting and engraving. It is constructed from multiple layers of wood veneer, bonded together with adhesives that can vary in composition. These layers can affect how the laser interacts with the material, influencing the quality of cuts and engravings. Factors such as feed rate, power settings, and focus alignment play critical roles in determining the final output. Adjusting these parameters carefully can make the difference between a smooth, clean cut and one marred by charring, inconsistent depth, or incomplete engraving.

For cutting plywood, the JTech 44W laser offers the ability to handle a wide range of thicknesses, provided the settings are calibrated correctly. Feed rate, measured in millimeters per minute (mm/min), determines how quickly the laser moves across the material. Faster feed rates are suitable for thin plywood, while thicker sheets often require slower speeds to allow the laser to cut through effectively. Power settings, on the other hand, control the intensity of the laser beam. Higher power is necessary for cutting, while engraving demands lower levels to achieve fine details without scorching the surface.

One of the standout features of the JTech 44W laser is its precision, which is heavily influenced by proper focus and alignment. Ensuring that the laser’s focal point is accurately positioned on the material’s surface is crucial for consistent results. Additionally, using laser-compatible plywood with uniform layers and minimal voids enhances both cutting and engraving quality.

By mastering these elements, users can unlock the full potential of the JTech 44W laser, transforming raw plywood into intricate designs, functional components, and stunning artistic pieces. Whether you’re a hobbyist or a professional, understanding the nuances of this powerful tool can elevate your projects to new levels of excellence. In this article we;ll read about Jtech 44w Laser Mm/min Material Test Plywood.

What is the Jtech 44W Laser?

The JTech 44W laser is a effective diode laser machine designed for engraving and reducing a extensive variety of substances, along with wood, plastics, and positive metals. Renowned for its precision and versatility, it’s far a pass-to choice for hobbyists, artists, and experts inside the maker community. To unlock its complete capacity, users should carefully configure the laser settings for every cloth, particularly plywood, which poses precise challenges because of its composition.

Features of the JTech 44W Laser

This laser device boasts outstanding skills that make it perfect for precise engraving and efficient reducing duties:

Power Output: Delivers 44 watts of power for coping with a variety of substances.

Wavelength: Optimized for cutting and engraving tasks across more than one surfaces.

Compatibility: Integrates seamlessly with CNC machines, 3-d printers, and other platforms.

Precision: Offers excessive-decision output, making sure pleasant detail in engravings and easy cuts.

Understanding Plywood and Its Challenges

Plywood is a famous cloth in laser slicing and engraving tasks because of its fee-effectiveness, availability, and adaptableness. However, its layered shape—composed of thin sheets of wood bonded with adhesives—can complicate the reducing manner. The glue layers and variations in wood density often require adjustments to the laser’s settings for optimum consequences.

Factors Affecting Laser Cutting on Plywood:

Material Thickness: Ranging from thin sheets (1/8 inch) to thicker panels (3/4 inch or more), plywood thickness determines the laser’s feed rate and power requirements.

Glue Layers: Adhesives between layers can be denser than wood, affecting cutting depth and quality.

Wood Type: The type of wood veneer (e.g., birch, poplar) used in the plywood can influence the laser’s performance and the final finish.

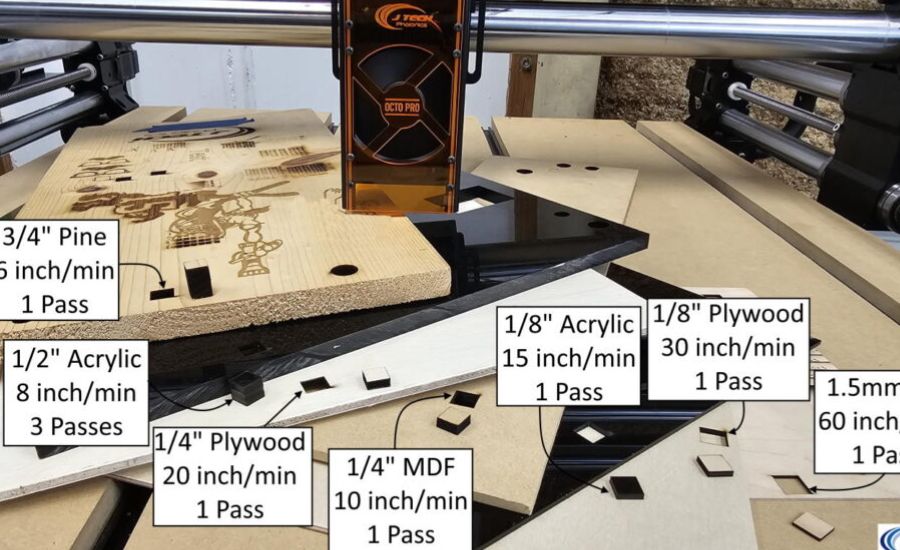

Recommended JTech 44W Laser Settings for Plywood

Cutting Thin Plywood (e.g., 1/8” or 3mm):

Power: 80–100%

Feed Rate: 300–400 mm/min

Passes: 1–2 passes if required

For thinner plywood, a high power setting combined with a moderate feed rate ensures clean cuts with minimal edge charring. Multiple passes may help achieve a smooth finish without excessive burning.

Cutting Thick Plywood (e.g., 1/4” or 6mm):

Power: 100%

Feed Rate: 200–250 mm/min

Passes: 2–3 passes

Thicker plywood requires slower feed rates and multiple passes to effectively cut through the layers of wood and adhesive. Proper adjustments minimize burning while ensuring clean edges.

By mastering these settings, users can harness the full power of the JTech 44W laser to create intricate designs and precise cuts, making it an essential tool for any project involving plywood or other materials.

Engraving Plywood

Engraving with a laser, such as the JTech 44W, requires lower power settings compared to cutting, as the focus is on removing only the top surface layer of the material. This allows for intricate designs and details without deeply penetrating the wood. For optimal results, understanding and fine-tuning laser settings for engraving on plywood is essential.

Example Settings for Engraving Plywood

Engraving on 1/8” (3mm) Plywood:

- Laser Power: 40–50%

- Feed Rate: 600–800 mm/min

- Passes: 1 pass

Using a higher feed rate with moderate power settings ensures that only the surface is etched, achieving detailed and clean engravings.

Engraving on 1/4” (6mm) Plywood:

- Laser Power: 50–60%

- Feed Rate: 500–600 mm/min

- Passes: 1 pass

Thicker plywood may need slightly increased power to achieve sufficient depth, particularly for designs requiring darker tones or broader coverage.

Factors Influencing Laser Cutting and Engraving Quality

Focus: Proper laser focus is critical for clean cuts and engravings. Adjust the laser head height to ensure precision.

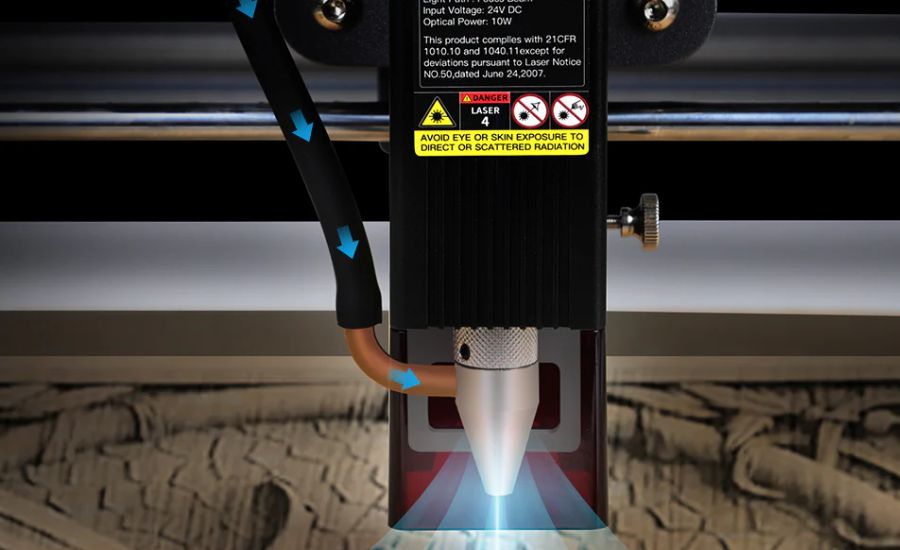

Air Assist: Integrating an air assist system helps remove debris during operation, reducing charring and improving edge quality.

Material Preparation: Ensure plywood is flat and clean. Warped or dusty material can result in uneven or inconsistent results.

Multiple Passes: Instead of increasing power significantly for cuts, use multiple passes to achieve clean penetration while minimizing burn marks.

Test Cuts: Conduct preliminary tests on scrap plywood to determine the ideal settings before starting your main project.

Best Practices for Laser Engraving and Cutting

Testing and Fine-Tuning

Always test settings on a spare piece of plywood before beginning your project. Adjust feed rates, power levels, and the number of passes to match your desired results. Keeping a record of successful settings can save time in future projects.

Minimizing Burn Marks

To reduce burn marks during cutting:

- Opt for faster speeds and lower power.

- Use masking tape on the plywood surface to shield it from charring. This tape can be peeled off after the operation for a clean finish.

Post-Cutting Finishing

Once the cutting or engraving is complete:

- Smooth the edges with fine sandpaper to eliminate residue or roughness.

- Remove any protective masking tape gently to reveal a polished surface.

By following these practices and optimizing settings for the JTech 44W laser, creators can achieve precision and professional-grade results in their woodworking projects.

Final Words

The JTech 44W laser is a powerful and versatile tool that excels in cutting and engraving plywood when settings are optimized. Understanding the material’s unique characteristics, like its layered construction and varying adhesive compositions, is key to achieving high-quality results. Properly adjusting power, feed rate, and focus ensures clean cuts and detailed engravings without unnecessary charring or inconsistencies.

For thinner plywood, higher feed rates with moderate power allow for quick, precise work, while thicker sheets benefit from slower speeds and multiple passes. Engraving requires lower power and a faster feed to maintain fine details on the surface. Additional tools like air assist and techniques like masking tape help reduce burn marks and improve overall quality.

By testing settings, maintaining the laser’s focus, and refining techniques, users can unlock the full potential of the JTech 44W laser, transforming plywood into intricate designs and professional-grade creations. Whether you’re a hobbyist or a professional, mastering these practices ensures stunning, precise results every time.

For more Information About Gadget visit risingperson